The first commercial NC machines were built in the 1950's, and ran from punched tape.

While the concept immediately proved it could save costs, it was so different that it was very slow to catch on with manufacturers. In order to promote more rapid adoption, the US Army bought 120 NC machines and loaned them to various manufacturers so they could become more familiar with the idea. By the end of the 50's, NC was starting to catch on, though there were still a number of issues. For example, g-code, the nearly universal language of CNC we have today, did not exist. Each manufacturer was pushing its own language for defining part programs (the programs the machine tools would execute to create a part).

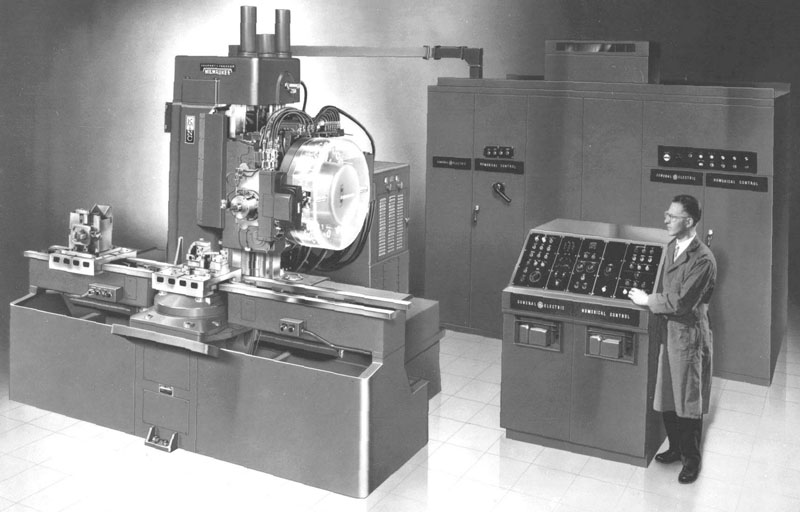

1959 CNC Machine: Milwaukee-Matic-II was first machine with a tool changer...

A number of key developments brought CNC rapidly along during the 1960's:

- Standard G-Code Language for Part Programs: The origin of g-code dates back to MIT, around 1958, where it was a language used in the MIT Servomechanisms Laboratory. The Electronic Industry Alliance standardized g-code in the early 1960's.

- CAD came into its own and started rapidly replacing paper drawings and draftsmen during the 60's. By 1970, CAD was a decent sized industry with players like Intergraph and Computervision, both of whom I consulted for back in my college days.

- Minicomputers like the DEC PDP-8's and Data General Nova's became available in the 60's and made CNC machines both cheaper and more powerful.

By 1970, the economies of most Western countries had slowed and employment costs were rising. With the 60's, having provided the firm technology foundation that was needed, CNC took off and began steadily displacing older technologies such as hydraulic tracers and manual machining.

US companies had largely launched the CNC revolution, but they had been overly focused on the high end. The Germans were the first to see the opportunity to reduce prices of CNC, and by 1979 the Germans were selling more CNC than the US companies. The Japanese repeated the same formula to an even more successful degree and had taken the leadership away from the Germans just one year later, by 1980. In 1971, the 10 largest CNC companies were all US companies, but by 1987, only Cincinnati Milacron was left and they were in 8th place.

More recently, microprocessors have made CNC controls even cheaper, culminating with the availability of CNC for the hobby and personal CNC market.